Metal fabrication today demands accuracy, consistency, and speed. As industries evolve, even small variations in metal components can affect performance, safety, and assembly. This is where CNC laser cutting plays a critical role. It allows fabricators to produce parts with tight tolerances, clean edges, and repeatable results at scale.

For manufacturers working with complex designs or high production volumes, precision is no longer optional. CNC laser cutting helps eliminate guesswork, reduce waste, and ensure every piece meets exact specifications.

What Is CNC Laser Cutting?

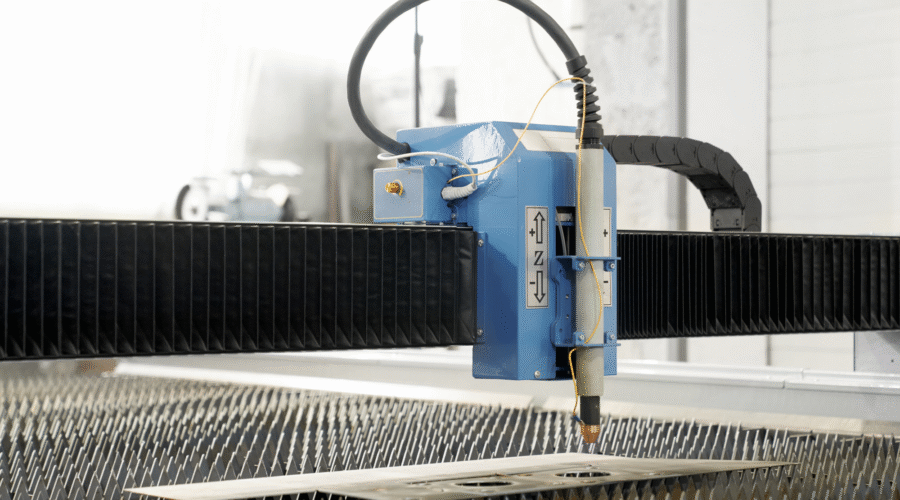

CNC laser cutting is a computer-controlled process that uses a high-powered laser beam to cut metal with extreme accuracy. The design is created digitally, programmed into the machine, and executed with minimal manual intervention.

The laser focuses heat on a precise point, melting or vaporizing the material while leaving surrounding areas untouched. Because the process is automated, results remain consistent across large production runs.

Key Benefits of CNC Laser Cutting

One of the biggest advantages of CNC laser cutting is how it improves overall fabrication quality.

- Precision:Cuts are exact, even on intricate shapes and tight tolerances.

- Speed:Faster cutting times help meet production deadlines.

- Clean Finish:Smooth edges reduce the need for secondary finishing.

- Less Waste:Accurate cuts maximize material usage and lower scrap rates.

These benefits directly translate into stronger parts, a better fit, and improved efficiency throughout fabrication.

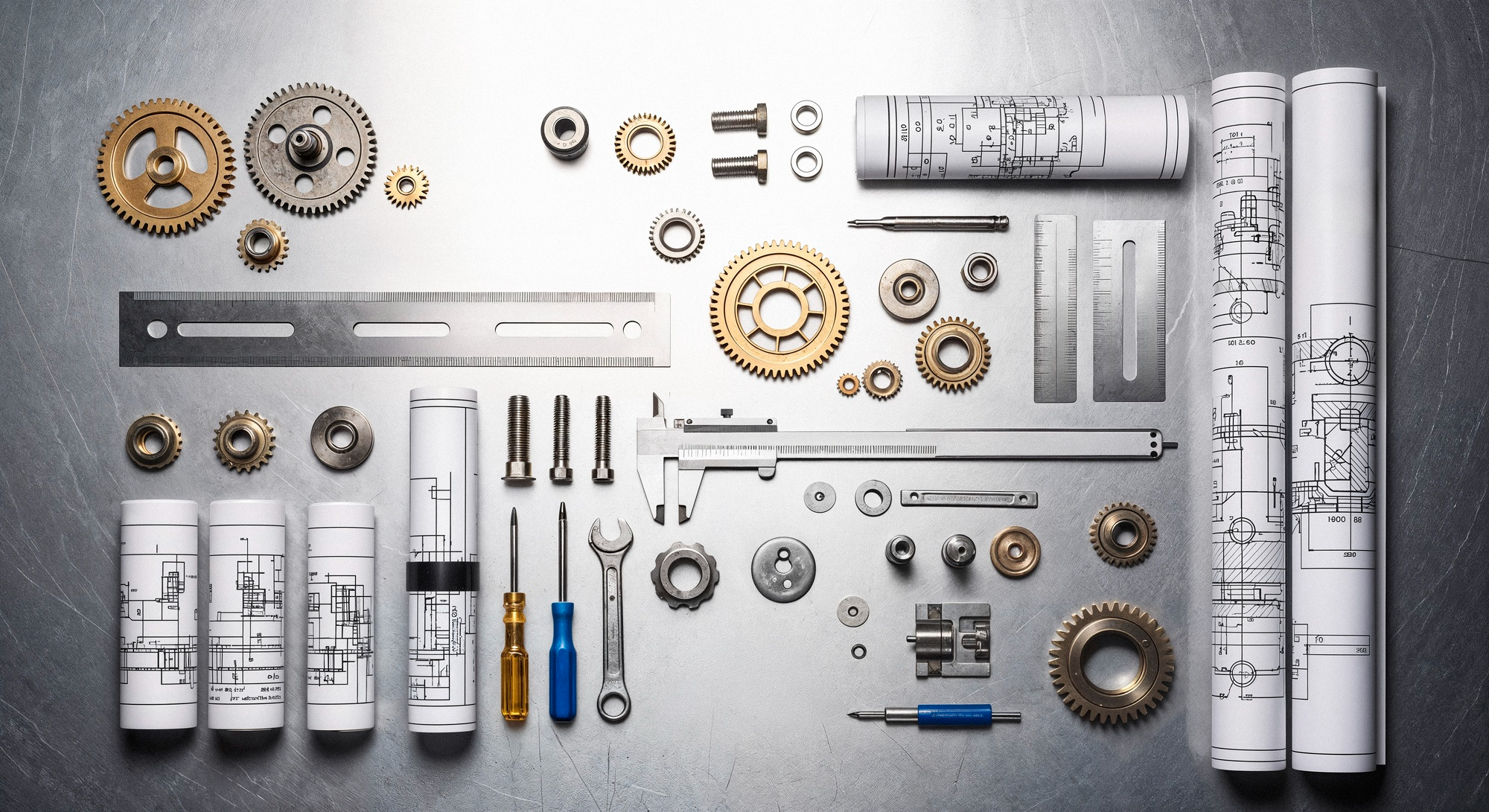

Materials Commonly Cut with CNC Laser Technology

CNC laser cutting is highly versatile and works with a wide range of metals used in industrial fabrication.

Common materials include:

- Steel

- Stainless steel

- Aluminum

- Brass

- Copper

Each material reacts differently to heat, but modern laser systems are designed to handle these variations without compromising cut quality.

Common Applications Across Industries

CNC laser cutting is used in many industries where precision and durability matter.

Typical applications include:

- Automotive components

- Industrial machine parts

- Electrical and control enclosures

- Structural brackets and frames

Because designs can be easily modified digitally, CNC laser cutting is ideal for both custom prototypes and high-volume production.

Why Choose JLL Fab for CNC Laser Cutting?

JLL Fab combines advanced CNC laser equipment with skilled operators who understand fabrication requirements across industries. Every project is handled with attention to detail, from the initial design to final inspection.

Clients benefit from:

- Modern CNC laser cutting machines

- Experienced fabrication professionals

- Reliable turnaround times

- Consistent quality control

This approach ensures parts are delivered ready for assembly or finishing.

The CNC Laser Cutting Process at JLL Fab

The process is structured to maintain accuracy at every stage:

- Design:CAD files are reviewed and optimized for cutting.

- Programming:CNC programs are created for precision execution.

- Cutting:The laser cuts each part according to specifications.

- Inspection:Finished parts are checked for accuracy and finish.

This controlled workflow minimizes errors and ensures dependable results.

Conclusion

CNC laser cutting has transformed metal fabrication by improving accuracy, efficiency, and consistency. For manufacturers who value quality and reliability, it is an essential part of modern production. To learn how precision laser cutting can support your next project, contact JLL Fab today for a custom quote